Transforming dust into strength: Bass Point’s Kayasand project sets a new benchmark for sustainable concrete

In a major step towards sustainable construction and smarter resource usage, we’ve officially signed a contract for a cutting-edge 120tph Kayasand plant at Bass Point Quarry. Scheduled for completion by the end of 2026, it’s an important step in our ability to turn excess quarry dust into high-performance concrete sand, reducing waste, preserving natural resources and lowering production costs.

Excess quarry dust: a challenge and opportunity

Several of our quarries, including Bass Point, are facing significant stockpiles of excess dust. This can be converted into "man sand" (manufactured sand) by removing superfine particles (under 75µm) through a washing or dry separation process.

However, the angular particle shape of quarry dust presents a challenge. Materials used in concrete perform best when particles are well-rounded or cubical which aids workability and strength. While existing crushers can refine the shape of 10mm and 20mm aggregates, finer particles are notoriously difficult to shape effectively.

Because of this, man sand, with its angular particles, can only be used to replace a third of the natural sand in concrete mixes.

That’s where Kayasand comes in.

Kayasand: a game-changing technology

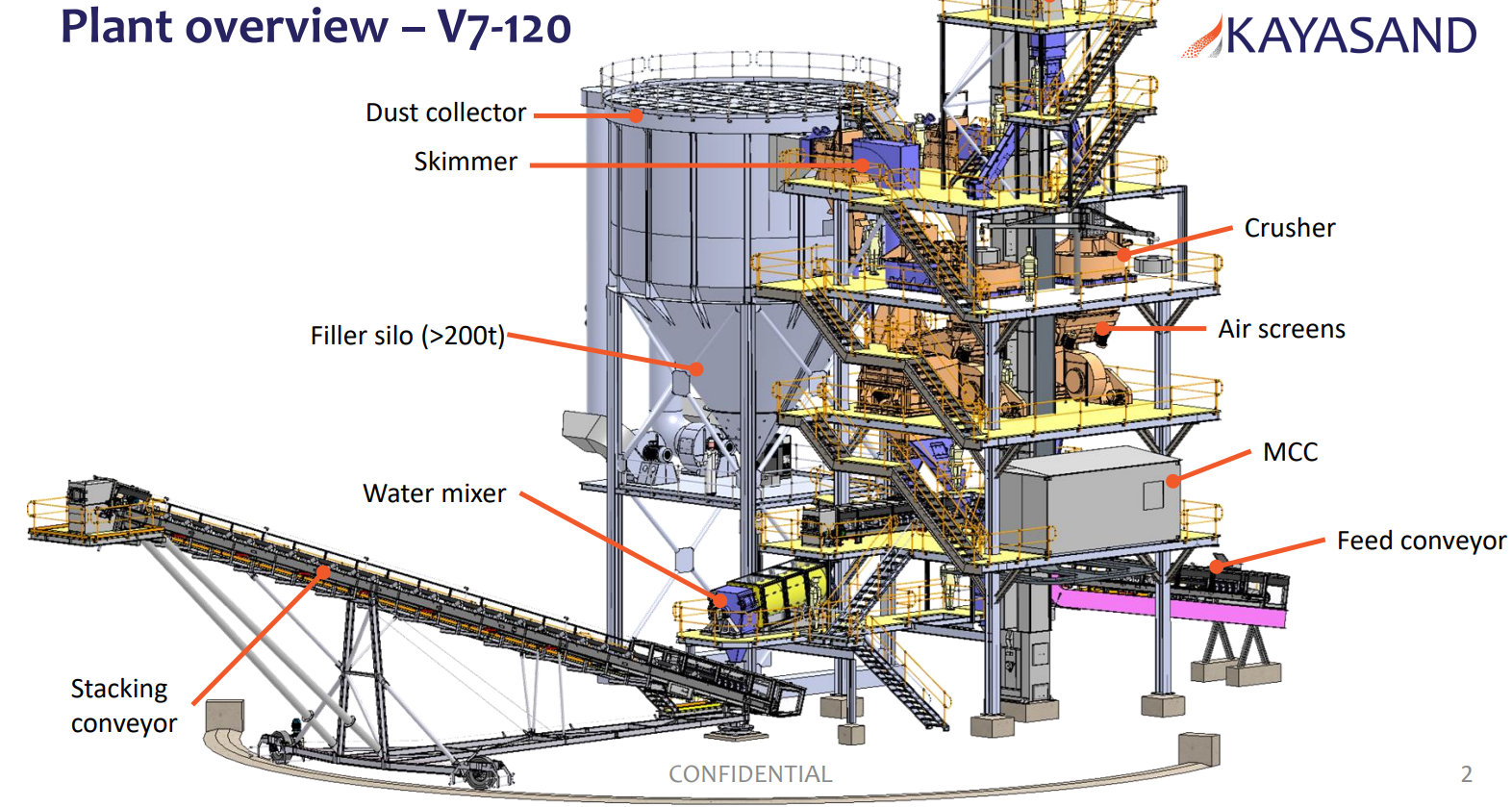

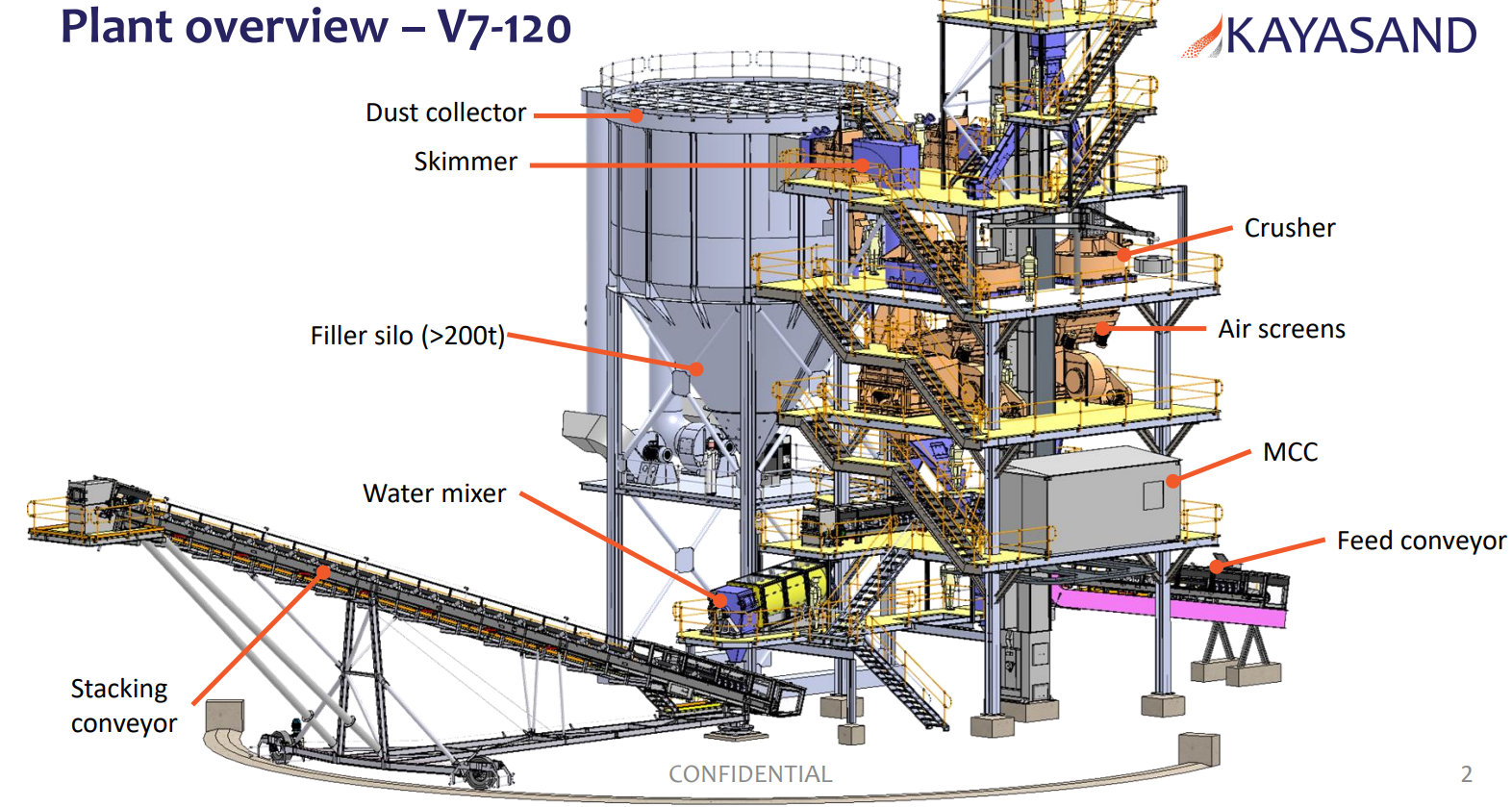

Kayasand, a leader in sand processing equipment, offers a specialised VSI (Vertical Shaft Impactor) crusher capable of shaping finer particles. Their integrated plant technology also provides high precision grading control, ensuring sand meets strict specifications across key sieve sizes.

This combination of superior shape and grading enables man sand to safely replace up to two-thirds of natural sand in concrete without compromising quality.

Back in 2021, a sample of Bass Point dust was sent to Japan for pilot processing through a Kayasand plant. The results were promising. In 2022, Kayasand-processed material was used in concrete slabs poured directly at Bass Point’s RMX plant, with excellent performance.

Future benefits of Kayasand plant

The new Kayasand plant will unlock a host of benefits:

• Better use of overstocked dust material

• Preservation of natural fine sand reserves

• Reduced need for externally sourced sand

• Lower equipment hire for existing man sand processing

• Up to 100% replacement of natural sand

This initiative is more than a technical upgrade. It’s a strategic investment in circular economy practices, cost-efficiency and sustainable growth.

We look forward to seeing the transformation unfold over the next two years and will continue to share updates as this exciting project progresses.

About Heidelberg Materials

Heidelberg Materials is one of the world's largest integrated manufacturers of building materials and solutions with leading market positions in cement, aggregates and ready-mixed concrete. We are represented in over 50 countries with more than 51,000 employees at almost 3,000 sites. At the centre of our actions lies the responsibility for the environment. As the forerunner on the path to carbon neutrality and circular economy in the building materials industry, we are working on sustainable building materials and solutions for the future. We enable new opportunities for our customers through digitalisation.

illustration.png.

Kayasand Plant.

illustration.png.

Kayasand Plant.